Home

A comprehensive resource for safe and responsible laser use

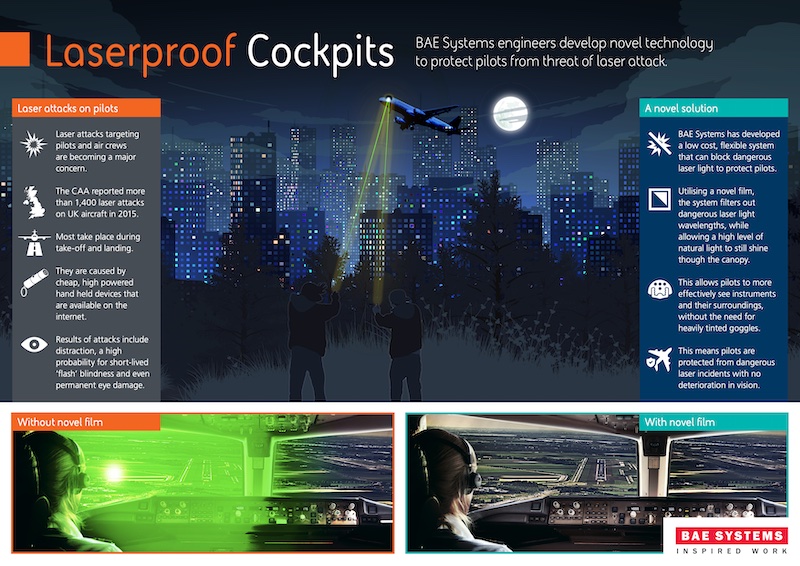

Windscreen laser protection for pilots

One proposal to help protect pilots from laser light is to put a film on aircraft windscreen windows, which will absorb or reflect unwanted laser light.

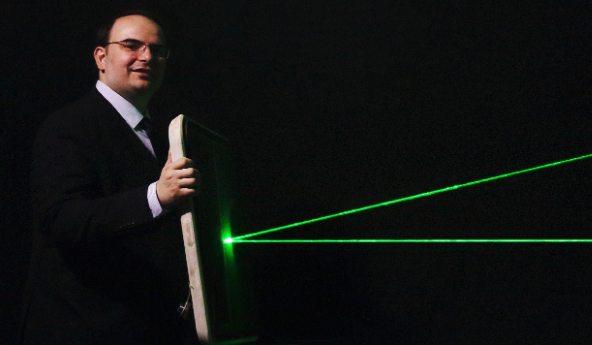

A demonstration aircraft windscreen containing film that reflects 532 nm laser light

Another proposal, in the early research stage as of March 2019, is to use liquid crystals between panes of windscreen glass. Incoming laser light would be detected and the liquid crystals would turn opaque, blocking or diffusing up to 95% of laser light regardless of color/wavelength. The blocking would occur only on parts of the windscreen illuminated by the light. The remainder of the windscreen would remain transparent. As soon as the laser light is gone, the blocked area returns to transparency. More information is here.

For both proposals, two major advantages are:

- The pilot does not have to do anything — the windows themselves protect the pilot.

- The pilot’s view of interior aircraft displays and controls is unchanged and uncolored — there is no color shift as can happen with laser protective glasses. (But note for windscreen film there could be a possible color shift or change for lights outside the windscreen, such as airport marker lights, so any film would have to be tested to ensure no adverse effects.)

The remainder of this page discusses only windscreen film, since the liquid crystal system is in early stages of development.

Status of windscreen film

As of early 2017, anti-laser film has only been applied to test aircraft flown by Airbus. On February 21 2017, Airbus announced plans to certify and deploy an anti-laser windscreen film made by a Canadian company, Metamaterial Technologies Inc. MTI’s “metaAIR” film uses nanoparticles to block laser light, and has some advantages over older dye and thin-film methods used in conventional laser protective eyewear.

On June 21 2017, MTI announced that aviation parts supplier Satair Group (an Airbus subsidiary) would market metaAIR film to all commercial aircraft, including Airbus and Boeing; this includes retrofitting older aircraft.

On September 12 2017, BAE Systems announced that they have successfully tested an anti-laser film in the laboratory. A multi-wavelength configuration was said to have 70% visible light transmission.

BAE did not indicate how similar or different their film is from MTI’s metaAIR. For this reason, the rest of this webpage is primarily about the MTI metaAIR film which has released more details and is further along in production and deployment.

For the most up-to-date status, check out LaserPointerSafety.com’s news items about anti-laser windscreen film.

Similarities with laser protective eyewear

In a broad sense, windscreen film is similar to Laser Glare Protection eyewear for pilots. In both cases, laser light is reduced in intensity so it cannot harm the pilot’s eyes and does not adversely block the pilot’s vision.

There should be as little reduction of non-laser light as possible. In other words, the windscreen film and eyewear should let through as much “normal” light as possible— especially since laser incidents occur at dusk, night and dawn when pilots cannot afford to have their vision darkened.

Also, there needs to be consideration of which wavelengths (laser colors) will be blocked or reduced. As of early 2017, most laser incidents involve 532 nanometer light which appears green. Usually, the more colors that are blocked, the darker the view, so it is not possible to guard against all potential laser colors.

Considerations especially for windscreens

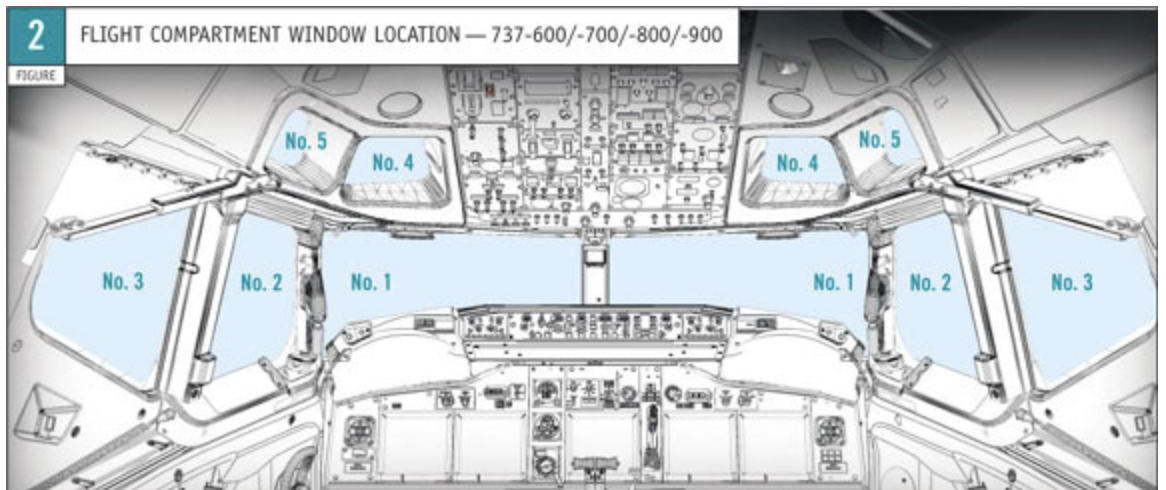

Windscreens on a typical commercial airliner (Boeing 737)

For windscreens, it is not a simple matter of just cutting off some film and adhering it to the inside of a window. Anything added to an aircraft — especially something that could potentially change pilots’ vision — must be certified. This is a long, complex and expensive process involving aircraft manufacturers, parts manufacturers and national regulators such as the U.S. Federal Aviation Administration (FAA).

In June 2017, MTI said that Satair Group expects to receive a Supplemental Type Certificate from the FAA, the European Aviation Safety Agency, and Transport Canada Civil Aviation in early 2018, with other jurisdictions to follow.

Each windscreen on a given aircraft has a different shape and a different orientation towards the ground. So the film itself must be tailored to the pilot’s view out that window. For example, the lower part of the film could block more laser light than the upper part, since laser illuminations do not come from above aircraft.

For maintenance and durability, the film is inserted as a layer at the time the windscreen is manufactured. There is a separate protective layer of glass or plastic so that a pilot or service person cannot directly touch the film.

MetaAIR film applied to an aircraft window during initial testing. For actual deployment, the film would cover the entire window surface and would be one of the layers in the entire windscreen/frame assembly.

Detailed information on Airbus’ windscreen plans

On February 27 2017, just after Airbus’ February 21 announcement, LaserPointerSafety.com spoke with George Palikaras, founder and CEO of Metamaterial Technologies Inc. The following questions and answers are not exact quotes, but are paraphrased and re-ordered from the interview with Palikaras, who reviewed and edited the material for accuracy.

As a brief introduction, MTI describes their metaAIR film as a highly transparent optical metamaterial filter created from polymer materials using nano-patterned designs which block and deflect incoming light. The primary use is for “premium laser protection.” The primary application to date is for aircraft windscreens, to help protect pilots from the over 10,000 yearly incidents worldwide where laser light is aimed from persons on the ground towards aircraft cockpits. MetaAIR is said to “not affect night-time vision as it is neutral in color and highly transparent.”

Q: What is the news from your February 21 press conference?

A: It is that we have partnered with Airbus to move to certification, commercialization and co-development of our metaAIR windscreen laser protective film. From our standpoint, this means that MTI is switching from R&D to full production. We’re hiring a lot more people.

Q: Can you discuss what wavelengths of laser light the metaAIR film will protect against?

A: For security reasons, I cannot discuss specific wavelengths. What I can say is that we can cover the entire visible spectrum with a 0.1 nanometer accuracy. If you want 532.1 nanometers versus 532.2 nm, we can move our notches to any wavelength.

We can notch as tight as 5 nm widths [e.g., +/- 2.5 nm from the central, desired wavelength] and as wide as 45 nm. We have not seen a requirement to go wider or narrower than that.

Q: Is there a variability in the lasers that are out there, being aimed at aircraft?

A: Yes, we have done a lot of work measuring lasers. We find that they are typically within +/- 3 nanometers of the specified wavelength.

Q: How about protecting against lasers coming from a wide variety of angles?

A: Not only can we specify one or multiple wavelengths, we can also block those wavelengths from specific directions. For example, a windscreen may be tilted back 45 degrees for aerodynamic reasons. We can protect a range from -70 degrees to +15 degrees, on one axis or both axes. We block light where the threat is believed to be coming from.

Q: How effective is the blocking or attenuation?

A: We have done close to Optical Density 6 [1,000,000 times reduction in brightness]. We can set it at whatever specification is desired. For aircraft windscreens, the OD will be less than 4. [This is a 10,000 times reduction in brightness. Note that it is not necessary to completely eliminate all laser light. It just needs to be attenuated to a manageable level for visual interference, and to ensure that the light level will not cause a potential eye injury. For some applications such as police helicopters, the pilot does need to see some of the laser light for functions such as locating a laser perpetrator.]

Q: What about any color shifts? For example, when green light is reduced, looking through film can give an overall magenta tone.

A: In the example, we can remove a little red and a little blue, and return proper color balance. We developed software to determine color balance. It uses an algorithm showing photorealistic outputs, so you can see what any color shifts would look like to the user. Once we have a desired color balance, we can move forward to prototyping.

Flight tests with Airbus show that our film allows pilots to have better contrast when taking off and landing — especially in low light or fog. The metaAIR film reduces the glare coming from city lights, or from lights on the aircraft that reflect off fog and thus light up the fog — similar to driving down a foggy road with headlights. We hope that once a pilot goes into his flight deck, he will be excited by the vision improvement.

Q: When might we begin to see in-service aircraft using your metaAIR windscreen laser protective film?

A: We cannot control the exact timing. Windscreens that have metaAIR included will have to be certified by applicable aviation authorities such as the U.S FAA, U.K. CAA and EASA (European Aviation Safety Agency). The main focus of the testing will not be on the film’s laser-blocking ability, but whether it passes the humidity, radiation and other environmental tests that show how long the film will last, which we have done a lot of work on. As this is the first time this product will be going through the certification process, we can’t speculate on timelines.

We can control the timing for our part, for manufacturing. We hope to have production by the end of Q1 2018.

Q: How long do windscreens typically last before they are replaced?

A: Through discussions within the industry, we have learned that they last between 7-10 years. Windscreens have to survive certain tests such as bird strikes. Our film will go on the inside of the windscreen, without affecting the windscreen’s properties or structure. There will be an anti-scratch layer which protects the film from pilot touching, maintenance, etc. We have not yet chosen this layer but we are in the process of doing that right now.

The longevity of the film is something we are taking into account, as with any new product. For in-use life, we will do accelerated environmental testing. This will add cost and time for releasing the product. But it is our hope that airlines will have peace of mind when it comes to our film.

Q: Will this be only for new aircraft, or also for retrofits?

A: The idea is that we will do retrofits from the get-go. We can also do line fits for brand-new aircraft; there are roughly 1,000 planes per year manufactured either by Boeing or Airbus. There is a much larger need for retrofitting existing fleets than brand new aircraft.

We believe we can do this during a Type A installation, at the gate, overnight, in a few hours depending on the number of aircraft windows. This means minimum disruption for the airline.

Our metaAIR laser protective film will be available to non-Airbus customers, and to existing windscreen manufacturers.

Q: What aircraft will benefit from this?

A: All aircraft. The product has similarities between the platforms, whether an Airbus A320 or a Boeing 737 or a Bombardier — they have the same style glass and compressed cabins. The environment is the same.

Helicopters may be different because of unpressurized cabins. We are definitely looking at helicopters, and general aviation is definitely in our plans. We will make sure we comply with all the right certification standards.

Once primary certification is achieved, hopefully supplemental type certificates will allow us to comply and certify for the rest of aircraft types.

Q: Since helicopters can have dramatically curved bubbles, how will the metaAIR film work in that environment?

A: Our film is thermoformable so with a little heat treatment it can be formed to any shape including helmet visors. Depending on how curved the substrate is, the optics change. We want to protect pilots from all angles of incoming laser light.

We have some advanced software that allows us to determine exactly how the metaAIR film’s angle protection needs to change, relative to the pilot’s head location. We have invented a process that can do a unique nanopattern in the volume of the film, fully customizable. We have full control over not only the wavelengths, filter strength and incoming angles, but also how and where the gratings are created in the material.

A bubble material would require variable gratings. We can pre-compensate the gratings. When the film is flat it will not protect from the desired angles but once we thermoform it into the final shape, it then protects from all specified angles.

We can do these non-uniform gratings in minutes, versus our competitors who would take hours or who could not do this at all depending on the technology they are using.

Q: What other applications can your film be used for?

A: In the area of vision protection, our film can be in glasses and helmet visors. We are working on this. Our films are compatible with night vision goggles. However, for aircraft applications we believe film on the windscreen is the ultimate solution.

We can protect sensors such as on surveillance cameras, satellites and autonomous vehicles. Google recently reported a case where a laser interfered with a self-driving car’s LIDAR [laser radar]. Instead of switching to radio waves [standard radar] we believe we can protect the LIDAR sensors.

There are applications for protecting ground vehicles, including police cars and military vehicles. We have an agreement with the U.S. Coast Guard to test films later this year to see if we meet their specs. If so, we’ll then go into field tests.

We are looking at optical filters for the medical diagnostics space where they use Raman spectroscopy. They need filters with very high OD to perform their analyses.

Basically, anywhere there is an optical filter that requires a user to see through with color balance and high transparency.

Q: What is the cost to line fit, or to retrofit, an aircraft with windscreens that include metaAIR?

A: We have not yet determined a cost. You cannot compare nanostructure technology to pure glass; certainly the cost will be higher.

If you think about eyewear, the cheapest pilot-suitable models are about $200 to $300. The area of the lenses is about 150 mm. If you could somehow put this over six windscreen windows, you can imagine how that would be an expensive solution.

We are working on pricing models so that metaAIR-equipped windscreens will be cost-effective for aircraft manufacturers and airlines. It will be a fair model that considers the research we have put in.

We point out that airlines will be saving money based on the risks of laser strikes. There are the cost of injuries to pilots’ eyes, both now and in the future as lasers become more powerful. A 1-watt laser that I purchased for $1800 a few years ago … now you can get that same power for less than $100 on the internet. There are the costs of a go-around on landing, or on missing connection flights, or because a laser-exposed pilot cannot fly the next segment.

Today most airlines don’t realize their costs because they have not been monitoring costs from laser strikes. We have a solution to put their mind at ease that also does not increase a pilot’s workload in the cockpit.

Q: Could a solution like this be required by national aviation authorities?

A: I do not see this as a requirement in the near term. But any requirement could happen depending on the number and severity of incidents — if they keep increasing. And if there was a catastrophic event, which is speculation right now.

Q: You compared eyewear to windscreen in terms of cost. How about other costs or negative effects?

A: Boeing has a page on their website which cautions against using eyewear because of losing symbology. [Boeing writes “…airlines should consider the drawbacks that are associated with them. Filtering light reduces the total amount of light entering the eye, which can adversely affect normal viewing, especially at night when most laser incidents occur. In addition, filtering green light can remove some green flight symbology on flight deck displays and change the appearance of some of the other colors used. As a result, protective glasses should be used with care.”]

Also, pilots using eyewear are taking on liability risk. If they forget eyewear at home or a hotel, does this mean they cannot fly? Do they have to check for scratches and maintain the equipment? Does each operator need to keep spares at each airport/gate? If they have the eyewear in the cockpit, do they have to add more checklist steps when landing? What if there is a lasing incident, is there liability if certain things happen?

Airbus’ ground testing and flight testing of our metaAIR film has given them enough confidence to give the green light that allows us to move forward. There will be more testing; they will fly enough to say, “Yes, this meets Airbus’ standards.” There may be additional requirements from agencies such as FAA or EASA.

Further information on Airbus’ windscreen plans

Aviation parts supplier Satair Group agreed on June 21 2017 to market metaAIR anti-laser protective film for aircraft windscreens. The Satair agreement will bring metaAIR to all commercial aircraft including Airbus and Boeing.

On July 5 2017, LaserPointerSafety.com spoke with George Palikaras, founder and CEO of Metamaterial Technologies Inc. The following questions and answers are not exact quotes, but are paraphrased and re-ordered from the interview with Palikaras, who reviewed and edited the material for accuracy.

Q: What is the procedure for an existing (in-use) aircraft to be equipped with the metaAIR film? Does it require removing or replacing the windscreens?

A: Our goal is to retrofit without taking any windows out. We want to make it as easy as possible. Applying the film takes a few hours. Airlines will do it as a “B check” at the hangar.

It does not require a large amount of training. Global MROs will get training for their staff to do this. Some airlines may have their own service departments; we will collaborate with them.

Q: Is the metaAIR film formulation different for each windscreen, since each one has a different angle to the ground?

A: Cockpit geometry has a very small variation between windows. There will be different film for different windows, or a different group of windows.

Our technology is capable of blocking laser light from any direction, and any wavelength [color]. Because of this, our capability is being looked at beyond commercial aviation. We are talking about public safety, military, helicopters, helmets and eyewear. We are looking to partner with companies where we can put our film on their technologies and products, to add value.

Q: Are there other technologies or solutions that are competitive?

A: On the competitiveness, we are very unique. We announced at the Paris Air Show that our product will also feature the option of UV protection. This goes beyond laser protection, and still fulfills our goal of safety of the pilots.

There have been some clinical reports about skin cancers that have developed in pilots. BALPA [British Airline Pilots’ Association] is concerned. We thought this was a very simple addition to our product. Our high performance window films will block over 99% of the sun’s broad spectrum UV radiation (UVA, UVB and UVC), resulting in a SPF factor of well over 100

This allows aircraft to fly higher. Every 1000-1500 feet higher you go, you get 10-15% additional UV radiation in the daytime. We offer 24/7 protection to pilots.

Q: What would be a typical or ballpark cost to add metaAIR film to a cockpit?

A: I can’t comment on cost specifically. I can say there will be lots of benefits.

We are hands down the least cost on a per centimeter basis. The value we add is beyond laser protection. The value proposition is unbeatable in my opinion. I don’t see any other technology out there that can offer so much on a per centimeter basis.

And of course it depends on volumes. The cost would be higher for one aircraft than for a larger fleet. There are volume discounts which our partners at Satair can discuss. They are in-between us and the customer. We rely on them to position at the right level.

Q: Is the laser threat leveling off, or getting worse?

A: There was a study done by a Masters student, a pilot, which showed a tremendously concerning percentage of underreported laser/aircraft incidents. I was told there is almost 50% underreporting of incidents by business jet pilots, and about 30-35% by commercial pilots.

I think the pilots are fed up — their reporting is not going anywhere, and industry is not doing anything. I spoke to a pilot who had been lased eight times. She said after the second time there was too much paperwork, so she did not report the others.

The trend for laser power is not coming down. The U.S. government is trying to ban the non-red colors. But it is very difficult to regulate consumer lasers. You look at YouTube where kids are showcasing their DIY 200-watt laser guns with stuff they salvage.

Q: How can MTI and metaAIR help pilots and airlines?

A: Our model is not the typical “here is your purchase price; install and forget it.” We want to be partners with airllines.

We see ourselves as leaders in laser protection. Not just the film, but market intelligence, threat intelligence, and working with committees such as SAE G10-OL and G10-T. We believe we can be on top of the threat, providing realtime reporting to the senior safety management at airlines.

We’re not just a product provider — but a solution provider, making sure if the threat moves, the product can also move to protect. This is where we see ourselves in a role for the future. Monitor the problem, but help the commercial, public safety, military and defense side.