Home

A comprehensive resource for safe and responsible laser use

Canada: UPDATED - Airbus to test windscreen anti-laser film

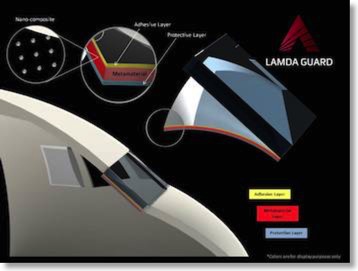

Lamda Guard’s “metaAir” film uses metamaterials, also called nano-composites, to reflect one or more laser colors without interfering with normal visibility. According to the company, the film can protect from beam angles up to +/- 50 degrees away from head-on. This has benefits when protecting cockpits against laser strikes, which can come from any angle.

It can be adhesively applied to glass or clear plastic; applications include eyewear, protective goggles and windscreens. Lamda Guard says that the Airbus tests on windscreens will mark the first time an optical metamaterial nano-composite has been applied on a large-scale surface.

General schematic of metaAir film. Click for larger image.

The metaAir film can be engineered either to absorb or reflect the desired wavelength(s). For aircraft application, the reflection approach is being used in order to block undesired light wavelengths from entering the cockpit. The reflection bandwidth is currently in the 15-20 nanometer range.

For the most common type of green laser pointer -- responsible for 93% of FAA reported incidents in 2013 -- with a wavelength of 532 nm, the film would block light from about 522 to 542 nm. Additional wavelength blocking can be added as well, such as the 445 nm blue used in powerful handheld lasers such as the Wicked Lasers S3 Arctic that has up to 2 watts (2000 milliwatts) output.

Two key advantages of blocking laser light at the windscreen are that pilots do not have to carry or use laser protective eyewear, and there is absolutely no interference with the visibility of aircraft instruments. In preliminary tests, the anti-laser film had a narrow enough bandwidth that it did not interfere with airport lights seen outside a cockpit.

Because of ultraviolet degradation to the adhesive layer that adheres the optical metamaterial to the windscreen, the film would need to be replaced after about 5,000 flight hours. This translates into overnight replacement roughly once every three years. The optical metamaterial itself would not have a flight hour restriction.

In addition to piloted commercial aircraft windscreens, Airbus will also be investigating related applications such as piloted military windscreens, UAV camera protection, and sensor protection for satellites and airborne platforms.

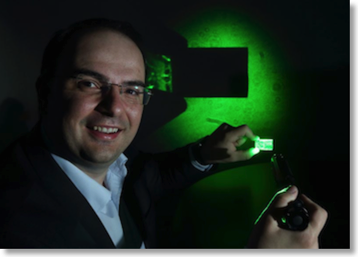

In this publicity photo, metaAir film blocks green light from a handheld laser that has a beam-expanding lens attached.

Lamda Guard president and CEO George Palikaras (pictured above) told LaserPointerSafety.com that the cost right now is “largely unknown. It is precision engineering similar to other large-scale multicoating technologies such as smart windows which cost thousands of dollars.” But he is looking towards reasonable pricing, and he also points out the cost-benefit of increasing pilot and passenger safety.

In applications where cost is a factor, such as small privately owned aircraft, it could be possible to apply the film to only a portion of the windscreen. This would give some protection (e.g., from head-on laser beams) and would allow an area of sufficient clear visibility.

Pascal Andrei, Airbus’s director of aircraft security, said testing and evaluating the Lamda technology could take a few years: “It has to be tested, validated and certified.” Bruno Gutierres, head of innovation accelerations and partnerships with Airbus said if tests prove successful, the metaAir film could be utilized in all the company’s products, civilian and military.

The Airbus trials will focus primarily on engineering requirements. These may vary between commercial requirements, such as fully blocking laser wavelengths, and military/law enforcement requirements, such as allowing some laser light through in order to identify threat locations.

Cost considerations will become more relevant after the film’s technical performance has been evaluated.

Samples are not yet generally available, since the agreement with Airbus is exclusive.

An FAA official contacted by LaserPointerSafety.com said that even if the material lives up to its potential, FAA certification for flight use would take time. He also indicated that the material would need to work with heads-up displays projected onto windscreens; one such display uses a green laser as the light source. [UPDATED June 5 2014: Palikaras wrote to LaserPointerSafety.com stating “...in my opinion having a reflective nanocomposite film on the inner glass surface means that HUDs could actually be brighter and better visualised than ever before right on the windscreen (something we are exploring) and at the same time providing the laser shielding protection.”]

Lamda Guard is one of three subsidiaries of Metamaterial Technologies Inc. of Dartmouth, Nova Scotia. The other subsidiaries are Lamda Lux Inc., which develops products to enhance the performance of LED lighting, and Lamda Solar Inc., which develops efficient solar panels. MTI has four full-time staff in Nova Scotia, one in New Brunswick, and ten in other parts of the world, including England.

According to a Wikipedia article, metamaterials “are assemblies of multiple individual elements fashioned from conventional microscopic materials such as metals or plastics, but the materials are usually arranged in repeating patterns. Metamaterials gain their properties not from their composition, but from their exactingly-designed structures. Their precise shape, geometry, size, orientation and arrangement can affect waves of light (electromagnetic radiation) or sound in an unconventional manner, creating material properties which are unachievable with conventional materials. These metamaterials achieve desired effects by incorporating structural elements of sub-wavelength sizes, i.e. features that are actually smaller than the wavelength of the waves they affect.”

Lamda Guard’s website has a page describing how its metamaterials are unique, with links to scientific and other publications from MTI staff and consultants.

From a PRNewswire release on Yahoo Finance, an interview with George Palikaras conducted June 4 2014, an article in the Chronicle Herald, and Wikipedia.